When thinking about thermal storage, the first thought of everyone is about water storage, which is cheap, widely available and in use for several years, which makes it reliable. But is it really so or are there other alternatives worth considering?

Water storages have been employed in domestic hot water and space heating or cooling systems for a long time and almost all producers of hydronics or HVAC equipment have their product lines for water storages. However, water storages are quite bulky…can you think about a water storage inside your house alongside the heat pump? No, your mental image will probably place the storage outside in combination with your solar water heater. The situation is even worst if we think about a storage meant for an entire building, which requires a dedicated technical room. Moreover, water storages belong to the category of sensible storage, systems in which the energy is stored in the form of sensible heat: each degree of temperature more (in case you want to store “heat”) or less (in case you want to store “cold”) means you have more energy in your system. However, this means that heat losses through the environment, especially in very cold climates during winter or very warm climates during summer can affect heavily the storage capacity. Let us have a more closer look on thermochemical storage.

What

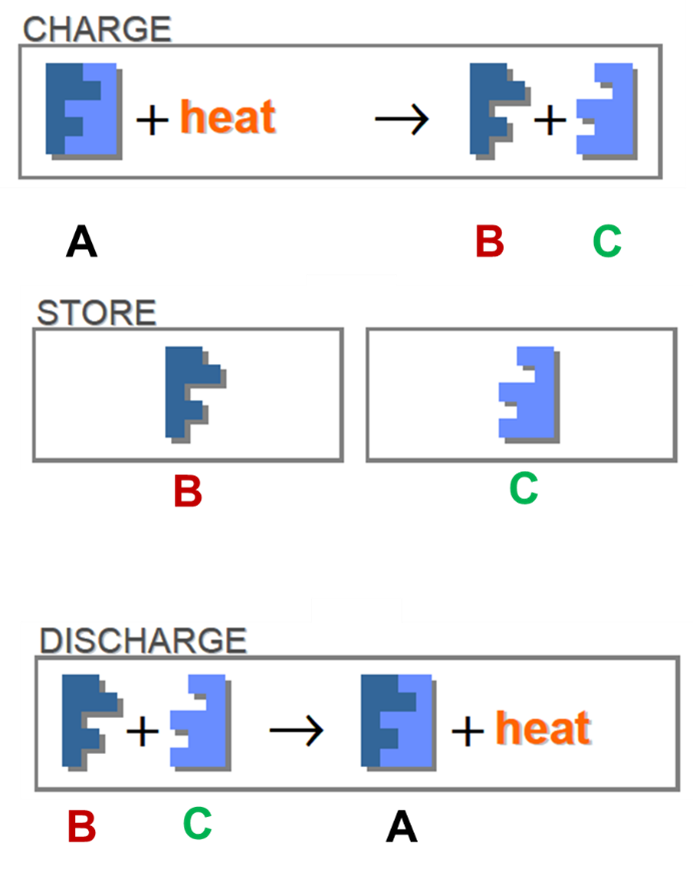

Thermochemical storage relies on a completely different principle: principle in the utilization of heat of reaction absorbed and released by a reversible reaction (Kerskes, 2016). A general description of the process is represented in eq. 1, where the reaction elements A and B react together to form the compound AB releasing thermal energy, ΔHreac (discharging phase) and the compound AB can be split in the reaction elements A and B by supplying thermal energy ΔHreac (charging phase).

A+∆Hreac ↔B+ C (1)

The working principle of the thermochemical TES is also depicted in Figure 1. It is evident that the system is able to keep thermal energy stored without any loss as long as the two reaction elements are kept separated. This feature is of great importance, indeed it allows considering this technology as one of the most promising for long-term (seasonal) TES.

Why

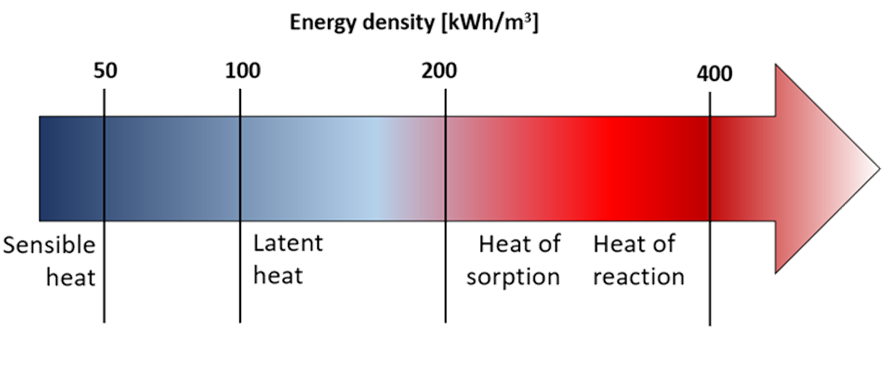

The energy density of thermochemical storage, i.e. the amount of energy that can be stored per volume of container, is much higher than for sensible storage (the traditional water storage), as shown in Figure 2. This means that instead of a storage of about 200 l (which is the standard for a single-family house), it is possible to have one of 50 l.

Where

Another peculiarity of thermochemical storage is the possibility of using the same system to work at different temperature levels, i.e. both for “heat” and “cold” storage, which is useful when the storage is connected, for example, to a heat pump that can work both in summer and winter mode.

Hypergryd Storage Activities

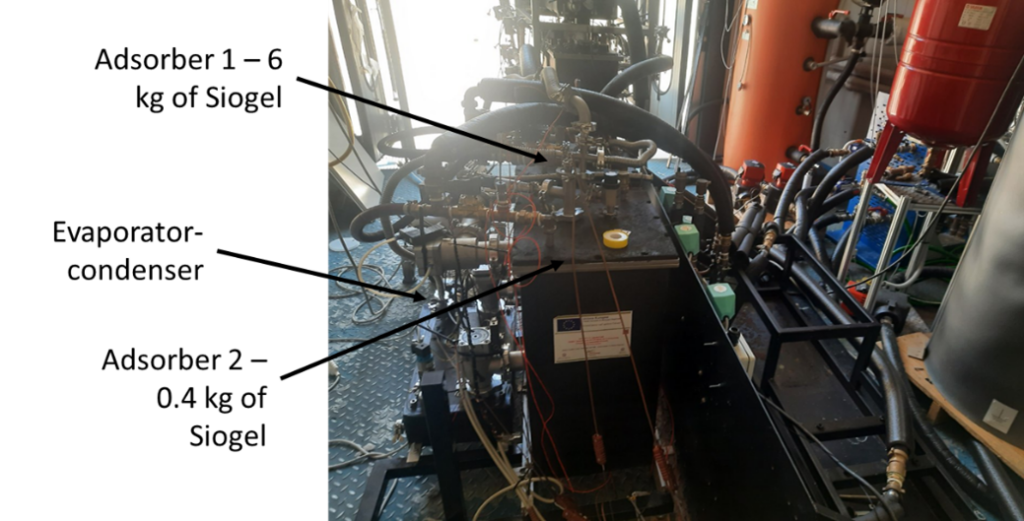

Within HYPERGRYD, the thermal energy storage activities are done jointly by CNR ITAE (Institute of Advanced Energy Technologies, belonging to National Research Council of Italy) and Sorption Technologies GmbH. So far, the activity has been devoted to the selection of storage materials that can perform well under the operating conditions foreseen for the project. In this case, it is possible to use sorption storages as decentralized storages at district/substation levels or even at building levels, charging them directly from the main district heating/cooling ring or in combination with heat pumps. This is especially useful in the new generation of DHC, that approach the concept of “temperature neutral” network, in which the temperature is kept as close to ambient temperature as possible. At the same time, the new generation of DHC is intended to accommodate a larger share of renewables inside the grids (thermal and electric), which requires suitable storage systems for peak shaving and load shifting The selection has been narrowed down to two composite materials, Silica gel/LiCl and Silica gel/CaCl2. At the same time, the best layout for the system is being investigated. An example of a small scale storage for definition of storage layout and currently under testing at CNR is shown in Figure 3.

What to Expect

The final prototype of sorption storage will have a modular design and will be tested for both heating and cooling. The target is to achieve 30 kWh storage capacity and a maximum power of 15 kW with an expected storage density of about 130 MJ/m3. The system will be installed in the living lab of IMP-PAN at KEZO facilities in Poland.

Written by Valeria Palomba from CNR ITAE